production process

Artificial turf stadium construction process

1, Prepare and test the base ground:Inspect the foundation to ensure it has a flat and smooth surface and appropriate slopes, making sure the foundation is qualified for installing artificial turf.

2,Measuring line:Locate the centers of the ground and the two semicircles, and according to these three centers locate the intersecting point of half-way lines and touchlines, and then determine the positions of functional lines and spot by using Pythagorean proposition.

3,Turf layout:According to drawing, position the turf rolls on the exact places along the touchline.The turf with white lines should be placed at the half-way lines and base line, and then lay out the rolls in order;

4, Preparing functional line:Cut white turf piece into strips(width to be as per actual need) for white functional lines(half-way lines,base lines etc.), and put them aside preparing for Green Artificial Grass Carpet installation

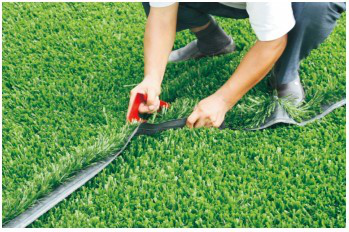

5, Glue and joint side of turf:The adjacent turf rolls must be join together with 20~30mm excess on both sides, then cut the excess part with a special cutting knife on the joint center and trim the cut to make the turf join perfectly together. After trimming, place the seam tape on the foundation surface and make the joint line of turf right on the middle of the seam tape. And then apply the adhesive to seam tape evenly with a rubber spreader, and press down the turf on both sides of the seam tape firmly.

6, Cutting white line:Measure and re-position the white line on the turf that has been all well joined on the ground. Cut the turf out and place the seam tape beneath the cuts. You can cut off the whole corner kick area,then cut the white grass into pieces, then place them back to form the arc line of a proper kick corner.

7, Trim the turf: after laying and joining the grass,trim the possible folds by a knife,cutting off the overlap parts and stick the turf firmly to the foundation.

8, Infill quartz sand & infill rubber granules:Place the sand piles on the finished lawn on different spots evenly at a distance of 4m from each other, then spread them evenly on the lawn(the quantity of sand depends on the pile height of the turf). Afterwards, use the combing machine to sweep the sand into the fibers and to comb up the fibers. Do this process once longitudinally and transversely. And the same for infilling rubber granules,also do the combing process longitudinally and transversely again.

9, Check and Acceptance:Inspect the entire finished lawn as per concerned standards and requirement. If any defects found, correct it.

10, Acceptance: cooperate to check and accept it.